Inline Bottle Filling Systems

ProSys offers a range of inline bottle filling systems tailored to various production needs. Our IL14 model is a continuous motion filler capable of processing up to 140 bottles per minute, making it ideal for high-speed operations. The IL6 model operates with intermittent motion for moderate production demands, efficiently filling up to 50 bottles per minute. Both systems are designed to handle a broad spectrum of product viscosities, from water-thin liquids to thick, viscous substances. Our advanced engineering incorporates servo drives and cutting-edge technologies to ensure precision and reliability. Optional closure systems are available to meet specific packaging requirements, providing a comprehensive solution for diverse market applications.

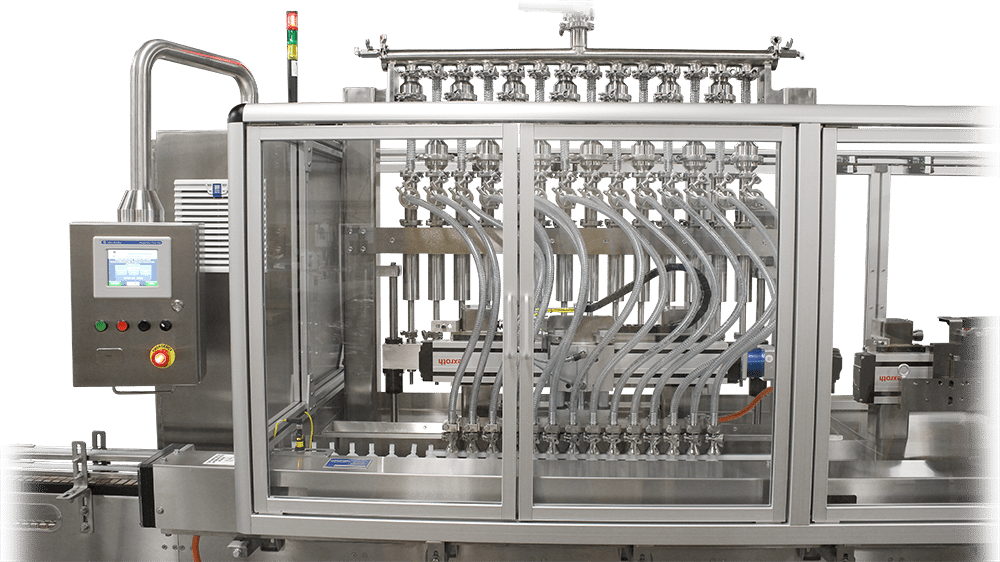

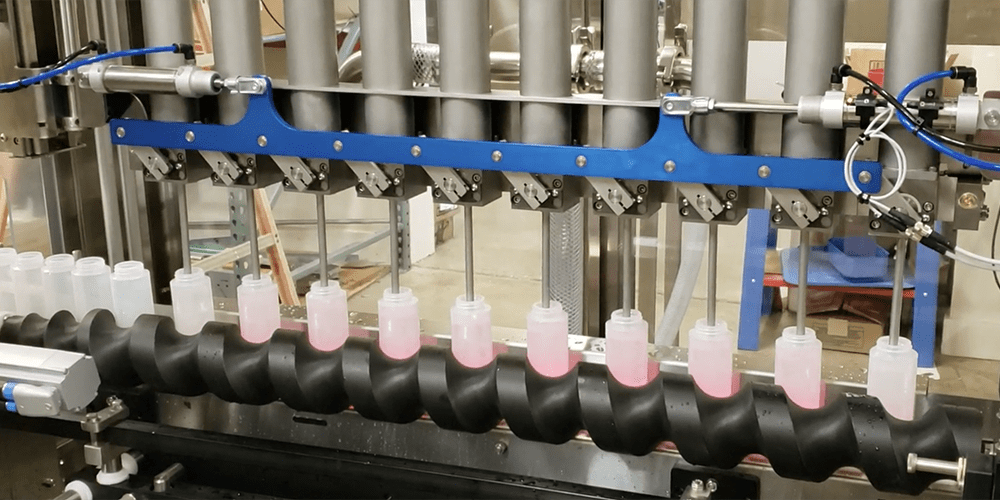

Inline Bottle Filling – Continuous Motion

High Speed automated filling closing of blow molded plastic bottles. System includes multi head filling via continuous motion in feed screw. Optional closure systems are available.

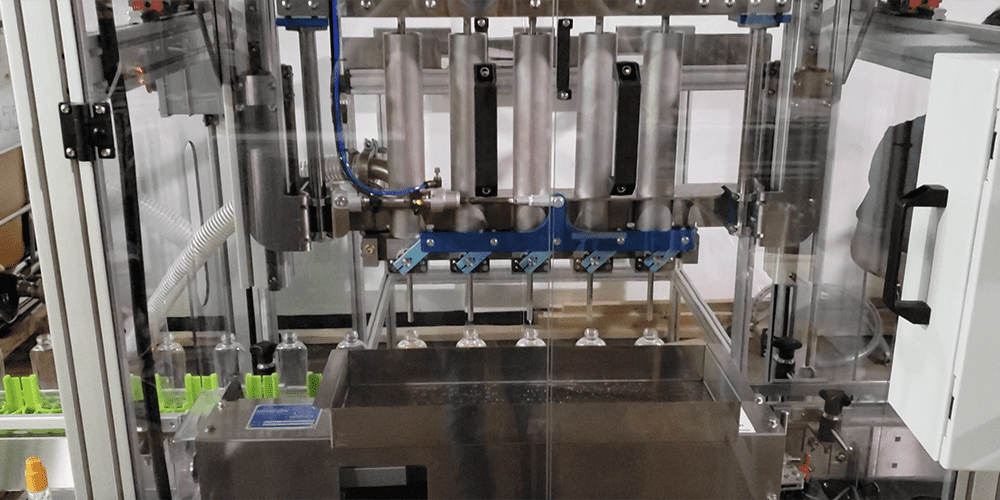

Inline Bottle Filling – Intermittent Motion

High Speed automated filling of plastic bottles. System includes multi head filling via intermittent motion in feed conveyor. Optional closure systems are available.

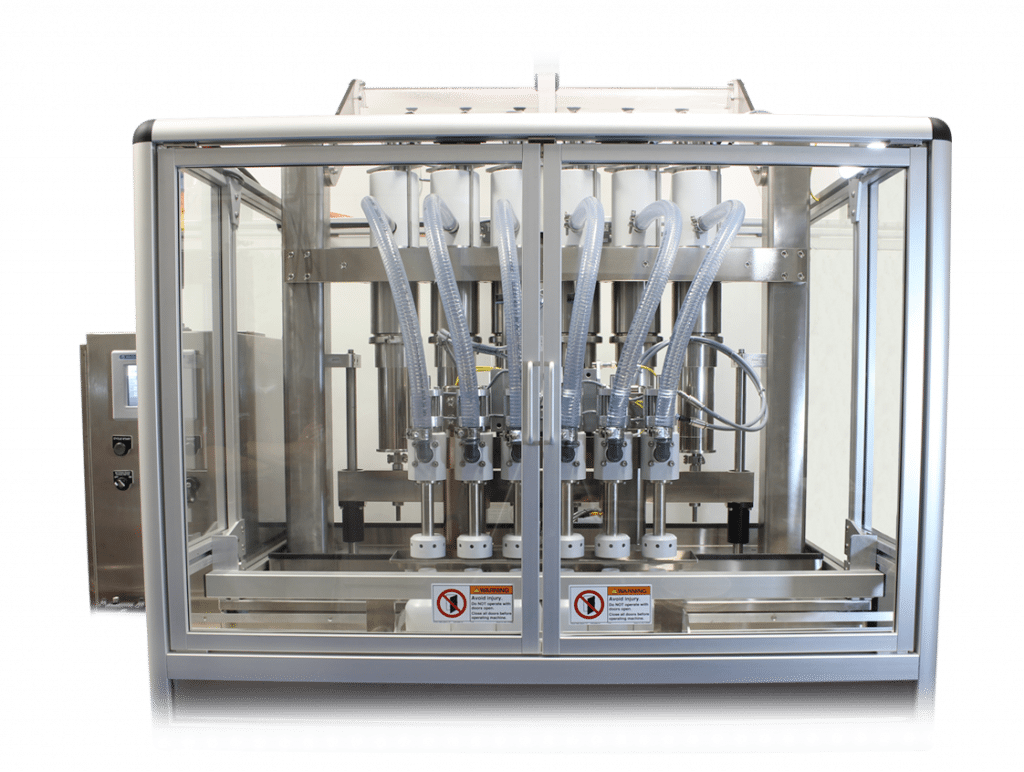

DF-100 Bottle Filling

Automated filling of plastic bottles. System includes multi head filling via intermittent motion in feed conveyor. Optional closure systems are available.

DF-200 Bottle Filling

High Speed automated filling of plastic bottles. System includes multi head filling via intermittent motion in feed conveyor. Optional closure systems are available.