ProSys airless pump filling systems are designed to work with various pump styles. Our engineers can design a system to fit your airless pump filling needs. ProSys airless pump filling systems are expertly designed for the precise and efficient filling of airless pump containers, ensuring product integrity and longevity. These systems are ideal for a range of applications, including cosmetics, pharmaceuticals, and skincare products that require a sealed environment to protect their formulations. With user-friendly designs and advanced technology, ProSys airless pump filling machines deliver consistent results and reduce waste. Their innovative features allow for quick changeovers and minimal downtime, boosting productivity for high-volume operations. Whether you need small or large-scale production, these machines provide the reliability and performance to meet industry demands.

Airless Pump Filling Systems

Filling Systems

MTS Airless Pump Filler – to 15 Per Minute

Semi-automatic system for filling and closing airless pumps. Standard systems include bottle load racks, diving nozzle fill station and pump head insertion stations. Automatic rack indexing is available.

RS8 Airless Pump Filler – to 35 Per Minute

Low speed automated system for filling and closing airless pumps. Standard systems include automatic sorting of bottles and pump heads, load station, fill station and closure station.

RS12 Airless Pump Filler – to 55 Per Minute

Medium speed automated system for filling and closing airless pumps. Standard systems include automatic sorting of bottles and pump heads, load station, fill station and closure station.

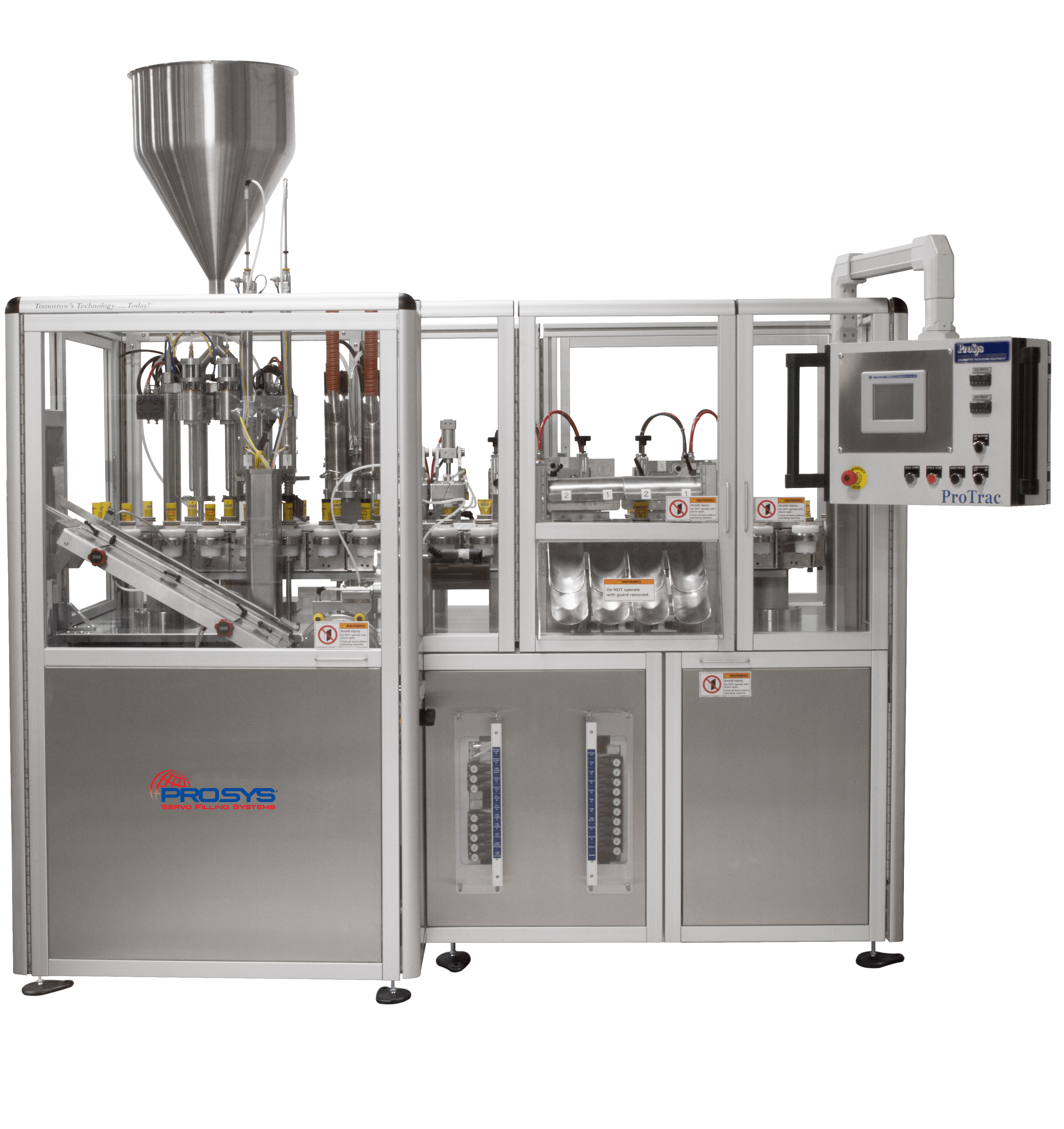

ProTrac Airless Pump Filler – to 90 Per Minute

High Speed automated systems for filling and closing airless pumps. Standard systems include automatic sorting of bottles and pump heads, dual load stations, Dual Servo fill stations and dual closure stations.