Hazardous Location (Explosion Proof) Control Systems

Hazardous Location control protection is a serious, complex safety issue. Ultimately, plant and personal safety depends on its correct implementation. ProSys engineers have developed considerable expertise in designing solutions for hazardous location control systems for cartridge, syringe, tube and custom filling machinery.

Hazardous Location control protection is a serious, complex safety issue. Ultimately, plant and personal safety depends on its correct implementation. ProSys engineers have developed considerable expertise in designing solutions for hazardous location control systems for cartridge, syringe, tube and custom filling machinery.

Area Classification & Definitions:

North America (NEC 500-5)

Class I Division 1:

Locations where ignitable concentrations of flammable gases, vapors, or liquids can exist all the time or some of the time under normal operating conditions.

Class I Division 2:

Locations where ignitable concentrations of flammable gases, vapors, or liquids are not likely to exist under normal operating conditions.

ATEX/IECex (NEC 505)

Zone 0:

Locations where ignitable concentrations of flammable gases, vapors, or liquids are present continuously or for long periods of time under normal operating conditions.

Zone 1:

Locations where ignitable concentrations of flammable gases, vapors, or liquids are likely to exist under normal operating conditions.

Zone 2:

Locations where ignitable concentrations of flammable gases, vapors, or liquids are not likely to exist under normal operating conditions.

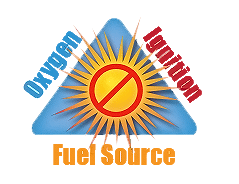

Hazardous Area Control Protection

To provide safe operating environment ProSys uses only the best safety control systems from well known suppliers for use in Class I, Division 1&2, Class II, Division 2 and ATEX 0&1 locations.

ProSys implements the following standard safety measures:

Intrinsic Safety

The available energy in the system is always low enough that ignition of the hazardous atmosphere cannot occur by ensuring that only low voltages and currents enter the hazardous area, and that all electric supply and signal wires are protected by safety barriers. Intrinsic safety also controls abnormal small component temperatures by using safeguards such as current limiting by resistors and fuses.

Pressurization

Equipment enclosures can be pressurized with clean air or inert gas and designed with various controls to remove power or provide notification in case of supply or pressure loss of such gases.

Encapsulation

A type of protection in which parts that could ignite an explosive atmosphere by either sparking or heating are enclosed in a compound in such a way that the explosive atmosphere cannot be ignited. The compound provides a barrier between the electrical apparatus and the explosive atmosphere.

Flameproof – NEMA 7

A method of protection where the equipment is contained within an enclosure, which will withstand an internal explosion of a flammable gas or vapor that may enter it, without suffering damage and without spreading to the external explosive atmosphere through any joints or structural openings in the enclosure.